Automotive Cable Assembly

Waterproof Automation Control Cable

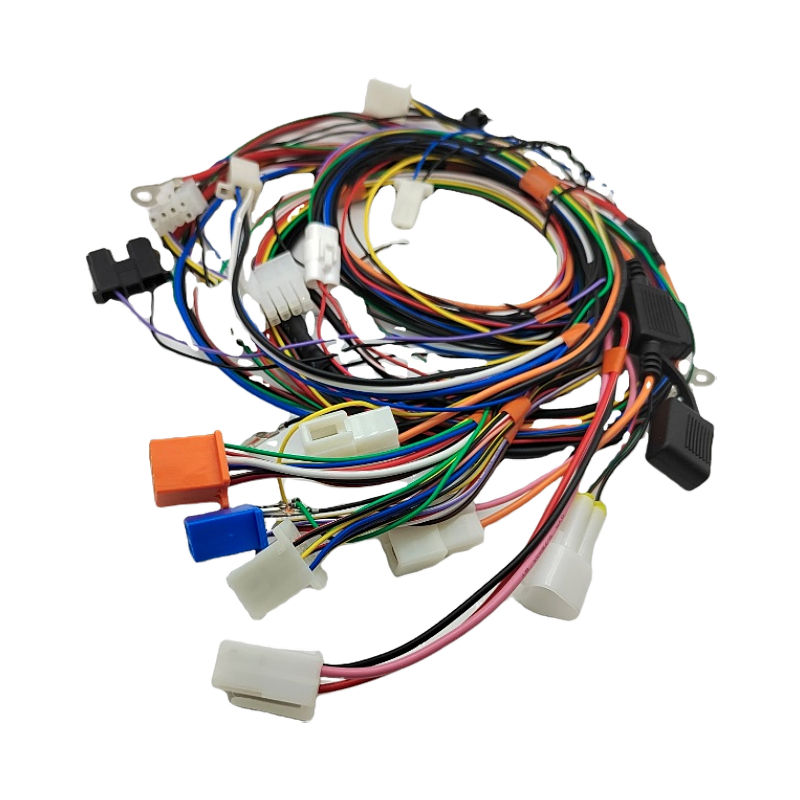

- Product description: Waterproof Automation Control Cable

A Waterproof Automation Control Cable is a type of specialized electrical cable designed to provide reliable electrical connections for automation systems while ensuring protection against water, moisture, and harsh environmental conditions. These cables are commonly used in industrial and outdoor automation applications where cables are exposed to water, humidity, or corrosive environments, and where it’s essential to maintain continuous power and data transfer without risk of short-circuits, damage, or performance loss.

Key Features of Waterproof Automation Control Cables:

1. Waterproof and Weather-Resistant:

o These cables are designed to be waterproof, often with a high IP rating (Ingress Protection), such as IP67 or IP68, meaning they can withstand immersion in water to certain depths and durations, or simply resist water splashes and humidity in damp environments.

o The cable’s outer sheath is typically made from materials such as PVC, TPE, or thermoplastic elastomers, which are durable, water-resistant, and able to resist other environmental stressors like UV rays and chemicals.

2. Designed for Control Systems:

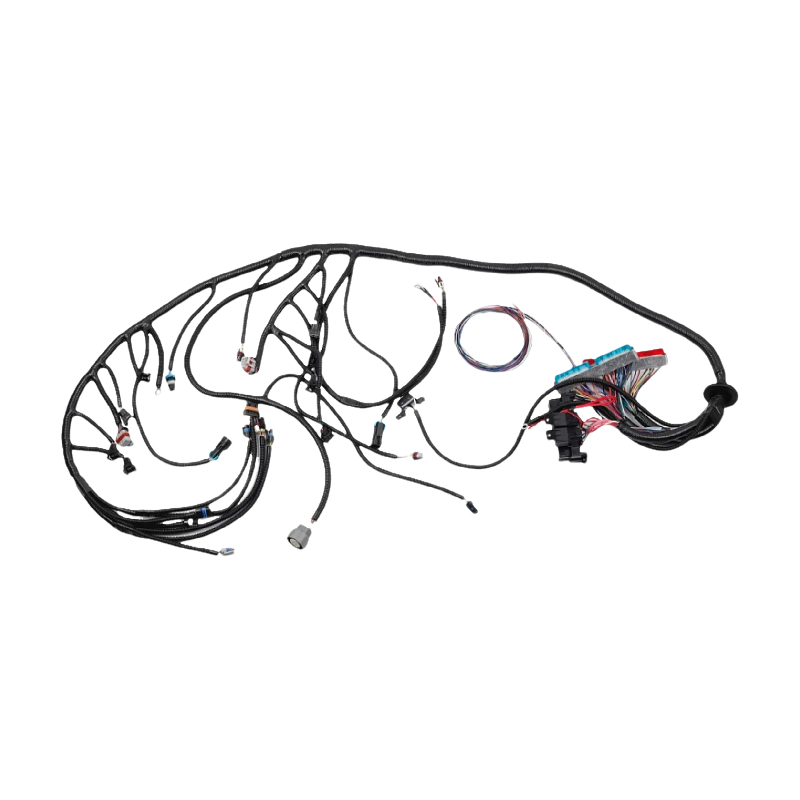

o Automation control cables are typically used to transmit electrical signals between different components of an automation system, such as controllers, sensors, actuators, and motors.

o These cables usually have multiple wires or conductors inside, designed to carry control signals for communication, switching, or regulating power between various devices in an automated environment.

3. Durability in Harsh Environments:

o Industrial environments, such as factories, manufacturing plants, automated assembly lines, and outdoor equipment, can expose cables to extreme conditions. Waterproof automation control cables are built to withstand abrasion, high temperatures, chemicals, oil, dust, and vibration—making them ideal for rugged and demanding applications.

4. Shielding for Signal Integrity:

o Many of these cables come with shielding (such as foil shields or braided wire shields) to protect the transmitted signals from electromagnetic interference (EMI) and radio-frequency interference (RFI), which is essential in maintaining the performance and reliability of the automation system.

5. Flexible and Easy to Install:

o To accommodate different installation scenarios, waterproof automation control cables are often flexible, allowing them to be routed through tight spaces or moved with automated machinery. They are available in a variety of sizes and configurations depending on the number of conductors, wire gauge, and shielding options required.

Applications of Waterproof Automation Control Cables:

1. Industrial Automation:

o Used extensively in industrial control systems such as programmable logic controllers (PLCs), motors, sensors, actuators, and other automation equipment in factories or manufacturing plants.

o These cables help manage and control the movement of machinery, assembly lines, robotic arms, and automated testing equipment, ensuring systems operate smoothly and efficiently.

2. Outdoor Equipment:

o Employed in outdoor automation systems such as automated irrigation, weather stations, solar power systems, or robotic landscaping tools that must operate reliably even in wet or humid conditions.

3. Agricultural Automation:

o Used in automated farming systems where control systems are exposed to the elements, such as automated irrigation systems, drones, or sensor networks that monitor soil conditions or crop growth.

4. Marine and Offshore Applications:

o Ideal for use in marine automation systems, such as automated winches, marine electronics, and underwater equipment, where the cable needs to be fully protected against saltwater and submersion.

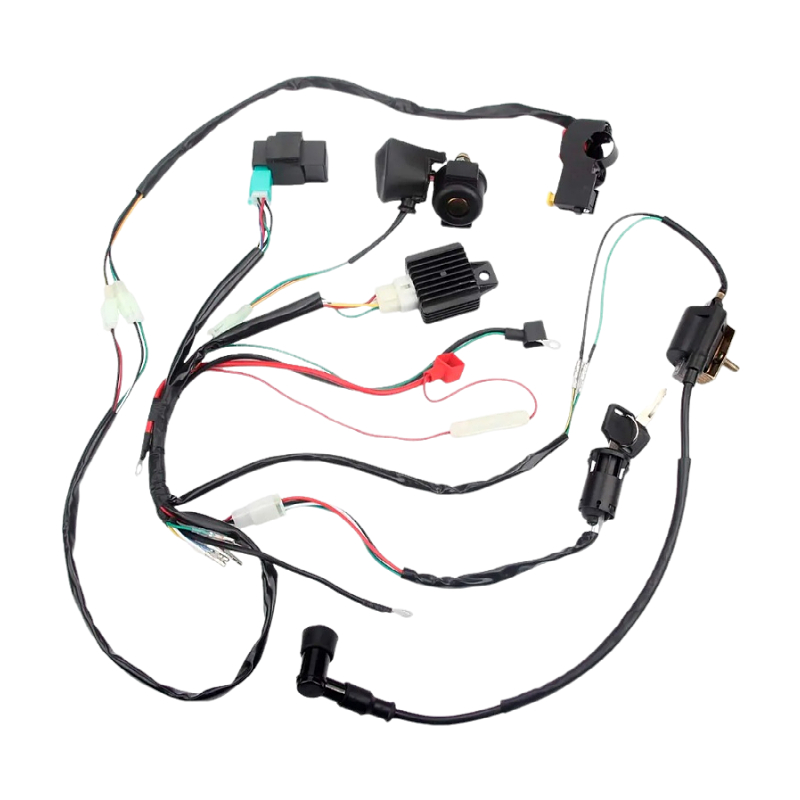

5. Transportation and Vehicles:

o Waterproof automation control cables are used in automated vehicles, such as self-driving cars, automated trains, or heavy-duty trucks, where exposure to rain, snow, or moisture is common.

6. Food Processing and Pharmaceutical Industries:

o In food processing plants and pharmaceutical manufacturing, these cables ensure safe and hygienic control of automated systems, such as conveyor belts, packaging machines, or cleaning systems, while being resistant to wash-downs and wet conditions.

Advantages of Waterproof Automation Control Cables:

1. Protection from Water and Moisture:

o The waterproof feature ensures that the cables continue to function correctly in wet or submerged environments, preventing short-circuits, corrosion, and signal degradation.

2. Durability in Harsh Conditions:

o These cables are specifically built to endure abrasion, extreme temperatures, chemical exposure, and mechanical stress, extending the lifespan of your automation equipment and minimizing downtime due to cable failure.

3. Reliable Performance:

o With proper shielding and insulation, these cables maintain signal integrity even in noisy industrial environments with heavy machinery or high electromagnetic interference.

4. Long-Term Cost Savings:

o The durability and longevity of waterproof automation control cables can result in lower maintenance costs, fewer replacements, and higher overall productivity in industrial automation systems.

5. Easy Installation and Flexibility:

o Many of these cables are designed to be flexible and easy to install, saving time during the setup of new systems or retrofitting older machinery with more modern automation controls.

Conclusion:

A Waterproof Automation Control Cable is a vital component in modern automation systems that need to operate in wet, humid, or exposed environments. These cables provide the necessary protection against water and other environmental factors, ensuring the safe and reliable operation of control systems in industries ranging from manufacturing to agriculture, marine, and transportation. With flexibility, durability, and the ability to carry both power and data signals, these cables ensure that automated systems remain operational and efficient in harsh conditions.

Categories

Latest News

Contact Us

Contact: Fiona Wu

Phone: 86 - 173 28414 818

Tel: 86 - 173 28414 818

Add: 20, Changtian Road, Hengli, Dongguan, Guangdong, 523852, China

Lankecms

Lankecms lankecms

lankecms

Lankecms

Lankecms