Inductor & Coil

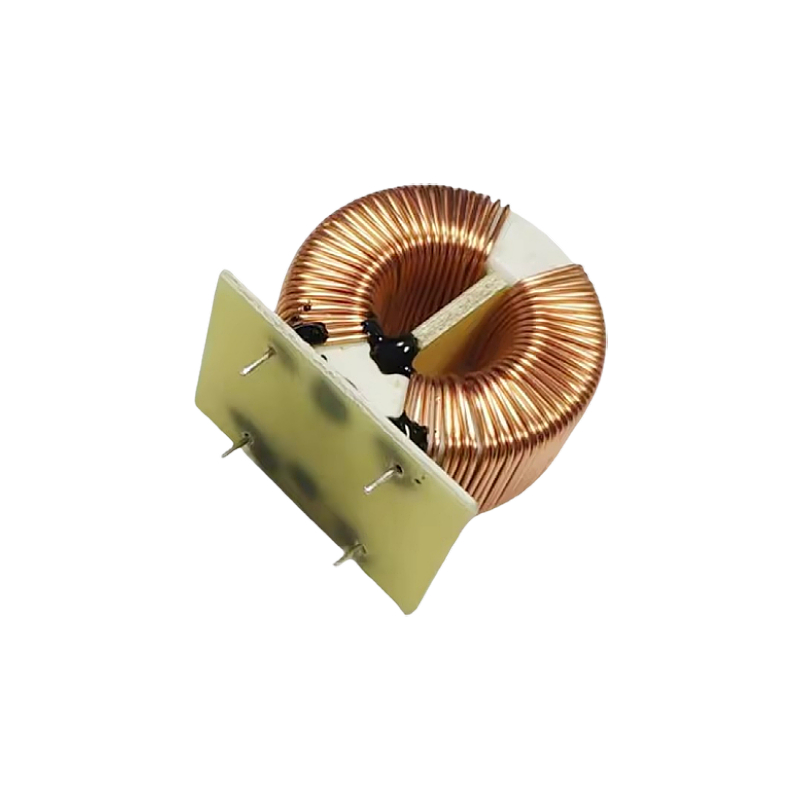

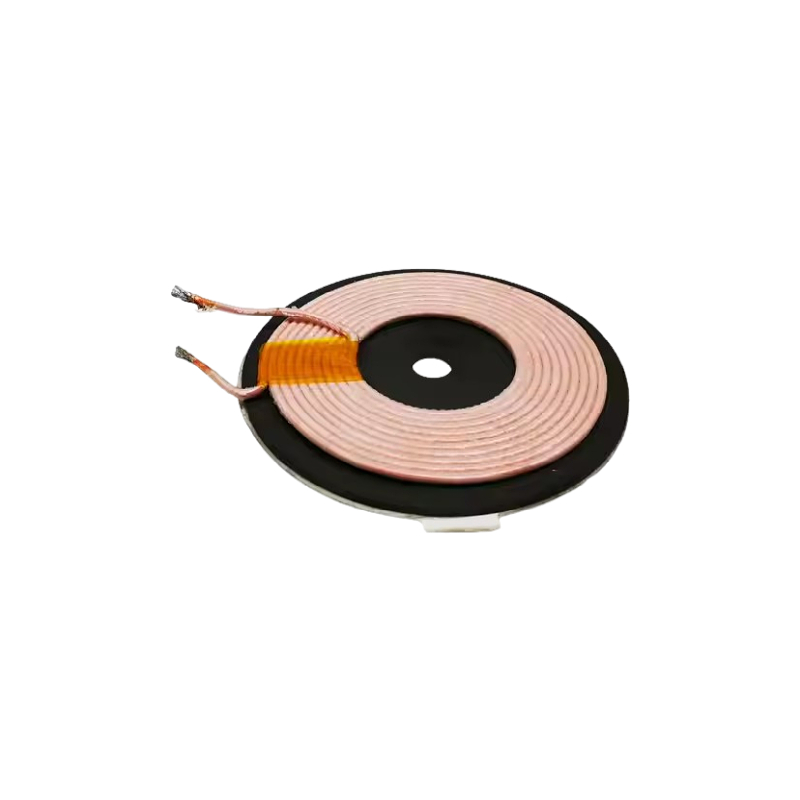

Customized High Power New Energy Storage Inductor

- Product description: High power inductors ensure optimal performance and efficiency in energy conversion systems.

Here’s a detailed about how the customized high-power new energy storage inductor work:

1. Basic Principles of an Inductor: Store energy in the form of a magnetic field when an electric current flows through them. This stored energy can later be released or used to smooth out fluctuations in current.

2. High-Power Inductor for Energy Storage Systems: It needs to be designed to withstand these conditions and ensure reliable performance in the system.

- Energy Storage and Conversion: Energy storage systems often use inductors in power conversion circuits (e.g., DC-DC converters, DC-AC inverters) to store or release energy in an efficient and controlled manner. These inductors are responsible for converting and regulating power between batteries, supercapacitors, or energy storage units and the load (e.g., an electric vehicle motor, renewable energy grid, etc.).

- Charging and Discharging Cycles: When charging or discharging a high-energy storage device like a battery, the inductor helps manage the current flow to ensure the process happens efficiently and without excessive heat generation. During high-power operations, the inductance helps prevent the sudden rise or fall of current, which can be damaging to the battery or capacitor.

- High Power Demands: In high-power applications such as electric vehicles (EVs) or grid-scale energy storage systems, the power levels can be extremely high. A customized high-power storage inductor needs to handle this load efficiently, which means:

3. Role in Efficiency and Power Conversion: They are crucial for optimizing the efficiency of energy storage systems. Efficiency is a key factor, especially in applications where maximizing energy retention (like in EVs or grid storage) is important.

4. Customization of High-Power Inductors for Energy Storage

The customization of inductors for high-power new energy storage systems focuses on the following design parameters:

- Core Material: The core material is selected based on its ability to handle high currents and power levels. Materials like ferrites (for high-frequency applications) or powdered iron (for higher power and lower loss) are commonly used.

- Inductance Value (L): The inductance must be carefully chosen to match the required current regulation and voltage conversion needs of the system.

- Size and Form Factor: Depending on the application, the physical dimensions of the inductor will be customized to fit the system design and optimize performance without taking up excessive space or weight, which is especially important in applications like electric vehicles.

- Current Rating: High-power inductors are specifically designed to handle large amounts of current without suffering from saturation or excessive heat buildup, as high currents can cause damage to standard inductors.

Application: The inductor's customization ensures that it can handle the high currents and voltages typically required in electric vehicles, renewable energy grids, and large-scale energy storage systems while minimizing energy losses and preventing damage to sensitive components.

Categories

Latest News

Contact Us

Contact: Fiona Wu

Phone: 86 - 173 28414 818

Tel: 86 - 173 28414 818

Add: 20, Changtian Road, Hengli, Dongguan, Guangdong, 523852, China

Lankecms

Lankecms lankecms

lankecms

Lankecms

Lankecms