Inductor & Coil

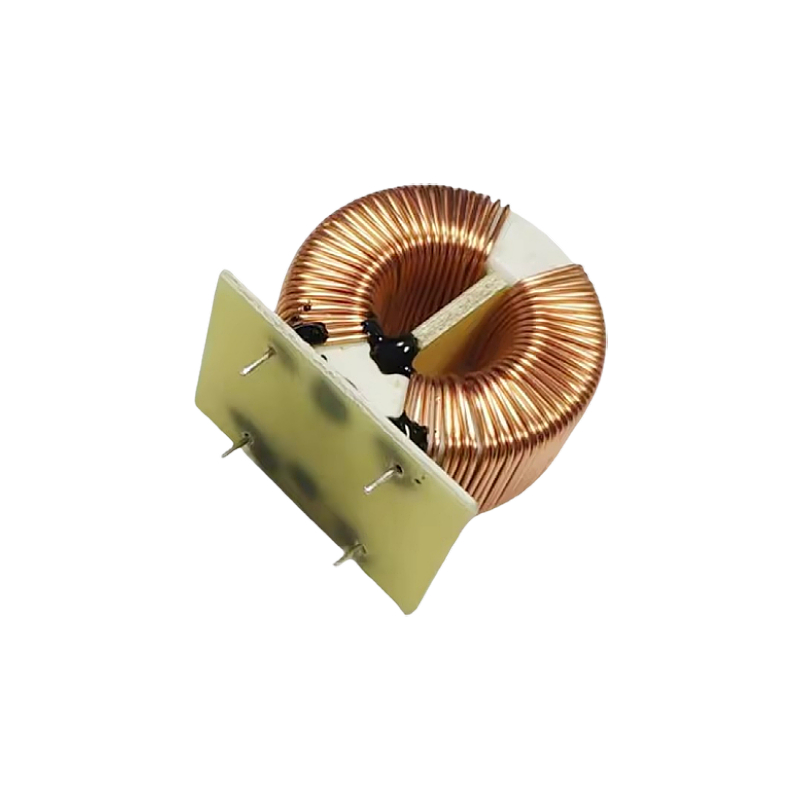

Copper Wire High Current Power Inductor

- Product description: A high-current inductor works based on the same fundamental principles as any standard inductor, but it is designed to handle higher amounts of current without suffering from overheating, saturation,

Here's how it works and what makes it suitable for high-current applications:

Basic Function of an Inductor

An inductor is a passive electrical component that resists changes in current. When current flows through an inductor, a magnetic field is created around it. If the current changes, the inductor generates a back electromotive force (EMF) that opposes this change, as described by Lenz's Law.

Key Factors for High-Current Inductors

1. Core Material: The core material of the inductor plays a significant role in determining its ability to handle high currents.

o In high-current inductors, the core material is often designed to minimize core losses and prevent saturation (when the magnetic field becomes too strong and the core can no longer store more energy efficiently). Saturation reduces the inductance and can cause large voltage spikes.

o Common core materials for high-current inductors are soft magnetic materials such as iron powder, ferrite, or specialized alloys designed for low loss and high saturation thresholds.

2. Wire Gauge and Turns: The wire used to wind the inductor is often thicker in high-current inductors, allowing it to carry more current without overheating. Thicker wire reduces the resistance (and hence the losses) and allows higher current handling.

o The number of turns in the coil also affects the inductance and current handling. High-current inductors may use fewer turns of thicker wire to reduce resistance and heat generation.

3. Inductance and Current Handling: A high-current inductor is typically designed with a relatively low inductance value compared to inductors used in signal filtering. This is because high inductance would create too large a back EMF for fast-changing currents, which is undesirable in high-power applications.

4. Heat Dissipation: High currents generate heat due to resistance in the wire. High-current inductors are often designed with better heat dissipation properties, such as:

o Using larger surface areas for heat sinking,

o Utilizing open-frame designs,

o Employing cooling mechanisms such as forced air or liquid cooling in extreme cases.

5. Construction: High-current inductors might be built with multiple layers of wire wound around a core to increase current handling. The windings might also be spaced further apart to allow for better airflow and cooling.

Applications

High-current inductors are used in applications where significant power must be handled without loss or overheating, including:

- Power supplies (especially in DC-DC converters),

- Motor drives (e.g., for electric vehicles or industrial machines),

- Filter circuits (in power electronics for smoothing current),

- Energy storage systems (such as in inductive energy storage).

Key Challenges:

- Saturation: If too much current flows through the inductor, it can saturate the core, which limits the inductor’s ability to oppose the current changes and can lead to a loss of inductance. High-current inductors are designed to avoid this by using cores with high saturation points.

- Losses: Even though high-current inductors are designed to handle large currents, resistive losses in the windings and eddy currents in the core material can still lead to inefficiency and heat generation. Advanced materials and construction techniques aim to minimize these losses.

Summary

A high-current inductor functions by resisting changes in current, generating a magnetic field, and opposing fluctuations in current flow. It is specially designed to handle large currents by using thicker wires, specialized core materials, and careful construction to avoid overheating and saturation. These inductors are essential in power applications where high efficiency and reliability are needed.

Categories

Latest News

Contact Us

Contact: Fiona Wu

Phone: 86 - 173 28414 818

Tel: 86 - 173 28414 818

Add: 20, Changtian Road, Hengli, Dongguan, Guangdong, 523852, China

Lankecms

Lankecms lankecms

lankecms

Lankecms

Lankecms