Inductor & Coil

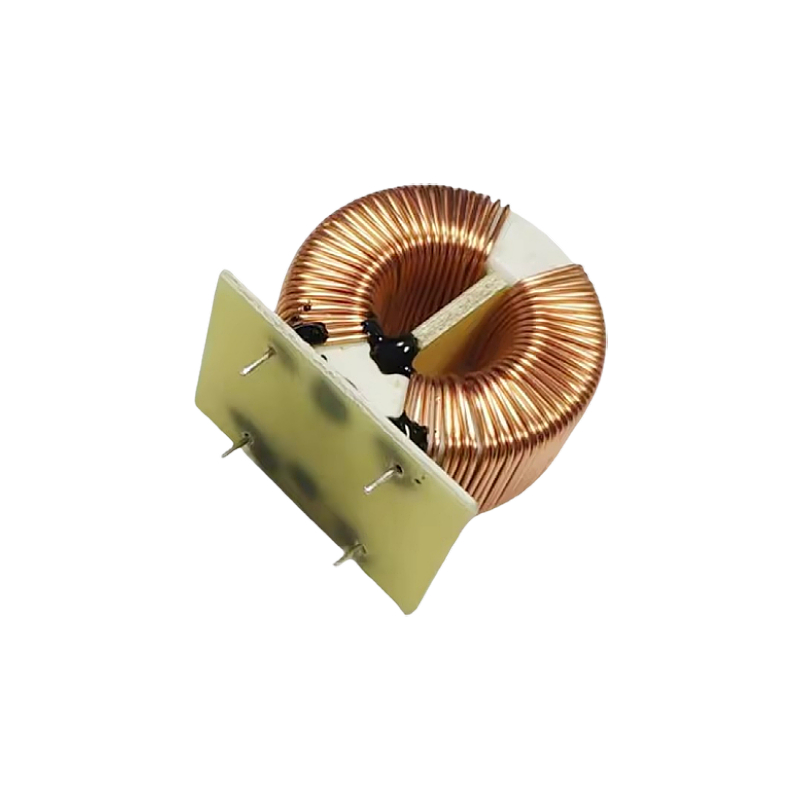

Power Inductor with FR4 Base

- Product description: A Power Inductor with an FR4 base functions by utilizing the principles of inductance, where energy is stored in a magnetic field created by the flow of electrical current. The FR4 base provides struc

Here’s a detailed breakdown of how a Power Inductor with an FR4 base works:

Basic Functioning of the Power Inductor:

1. Energy Storage in the Magnetic Field:

o When a current flows through the copper windings, it creates a magnetic field around the inductor. The core material, with its high permeability, channels and amplifies this magnetic field.

o The magnetic field is the form of energy that is stored in the inductor. The amount of energy stored is proportional to the inductance and the current.

2. Inductive Reactance:

o The power inductor opposes changes in current due to its inductive reactance. This is a key feature of inductors, which resist sudden changes in current by storing energy in the magnetic field and releasing it when the current fluctuates.

o The inductance (L) of the inductor determines how much opposition it provides to changes in current. Higher inductance means more energy can be stored, and it resists changes in current flow more effectively.

3. Filtering Action (Power Conversion):

o Power inductors are widely used in power supply circuits (like DC-DC converters or buck/boost converters) to smooth out the fluctuations in current or voltage. The inductor helps to filter high-frequency noise and smooth the ripple in power output.

o In a buck converter, for example, the inductor stores energy during the on-time of the switch (typically a MOSFET or transistor) and releases it when the switch is off, providing a steady current to the load.

o The inductor’s ability to store energy during the high-current phase and release it during the low-current phase is what enables power conversion circuits to provide a stable voltage or current output despite fluctuations in input voltage.

4. Magnetic Saturation:

o Every magnetic core material has a saturation point at which it can no longer efficiently store magnetic energy. When the current increases beyond this point, the core becomes saturated, and the inductor’s ability to oppose changes in current (its inductance) decreases.

o In high-power inductors, careful selection of core material and design parameters (such as core size, number of turns, and current limits) ensures that the core operates below saturation levels during normal operation.

Thermal Management:

- Heat Dissipation is a key concern in power inductors, especially in high-current applications where the resistance of the copper windings (known as DC resistance or DCR) and core losses can lead to significant heat generation.

- FR4 does provide some level of heat dissipation, but it’s not as thermally conductive as metal. Thus, power inductors often rely on factors like:

o Wire gauge: Thicker wire reduces resistive losses and heat generation.

o Core design: Optimized core materials and designs help minimize eddy current losses, which can contribute to heat.

o Surface area: The physical design of the inductor, including the use of larger winding areas and exposed surfaces, helps dissipate heat.

o In very high-current applications, additional heatsinks or active cooling systems may be used to manage thermal stress.

Key Benefits of Using FR4 in Power Inductors:

1. Cost-Effectiveness: FR4 is a widely available and relatively inexpensive material, making it ideal for mass-production applications.

2. Electrical Insulation: FR4 provides excellent electrical insulation between the inductor's components, ensuring that the windings do not short-circuit.

3. Mechanical Strength: FR4 provides a stable and robust base to support the core and windings, maintaining the integrity of the inductor under high current and mechanical stresses.

4. Thermal Stability: FR4 can handle moderate levels of heat, which is important in power inductor applications where heat dissipation is crucial. However, the heat tolerance is limited, so additional cooling strategies may be needed for very high-power designs.

Applications:

Power inductors with an FR4 base are used in a wide range of applications, such as:

- DC-DC Converters: For efficient power conversion in systems such as battery-powered devices, power supplies for electronics, and voltage regulators.

- Buck and Boost Converters: To step down or step up voltage levels in power management systems, especially in portable electronics.

- Filtering Circuits: To smooth out fluctuations in current and voltage, ensuring stable operation of sensitive devices.

- Power Supplies for Communication Equipment: Used in RF and communication devices for stable power delivery.

- Energy Storage Systems: Inductors are used in energy harvesting or storage systems to manage energy flow and smooth out power.

Conclusion:

A Power Inductor with an FR4 base functions by storing energy in a magnetic field created by current flowing through the windings, which are wound around a magnetic core. The FR4 base provides insulation, mechanical support, and helps with thermal dissipation. The inductor's primary role is to resist changes in current and to smooth voltage fluctuations in power supply circuits, enabling efficient power conversion. By carefully selecting the core material and optimizing the inductor’s design, power inductors can handle high currents and operate efficiently in power systems.

Categories

Latest News

Contact Us

Contact: Fiona Wu

Phone: 86 - 173 28414 818

Tel: 86 - 173 28414 818

Add: 20, Changtian Road, Hengli, Dongguan, Guangdong, 523852, China

Lankecms

Lankecms lankecms

lankecms

Lankecms

Lankecms