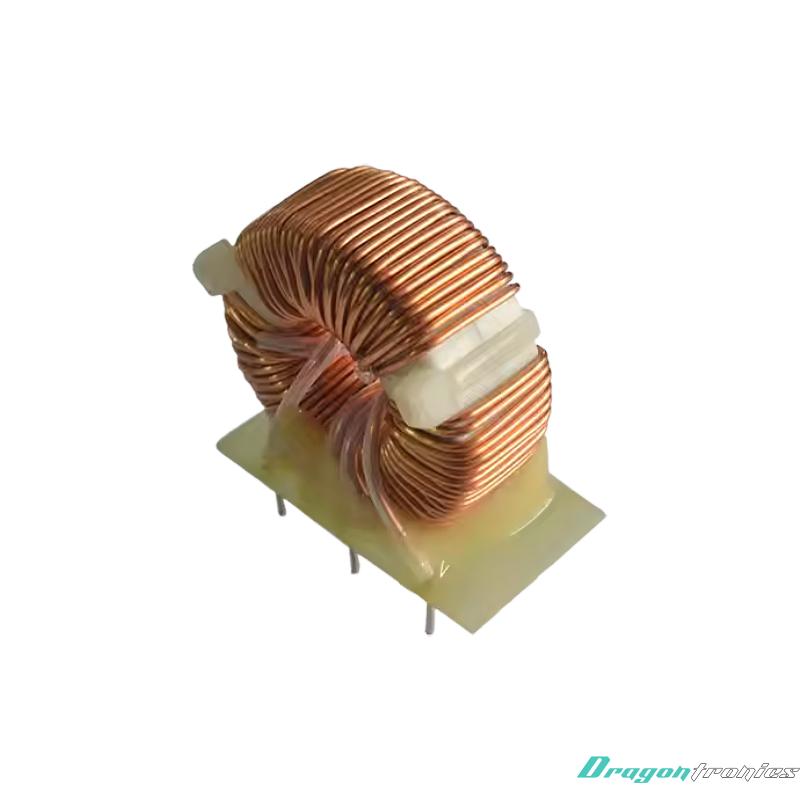

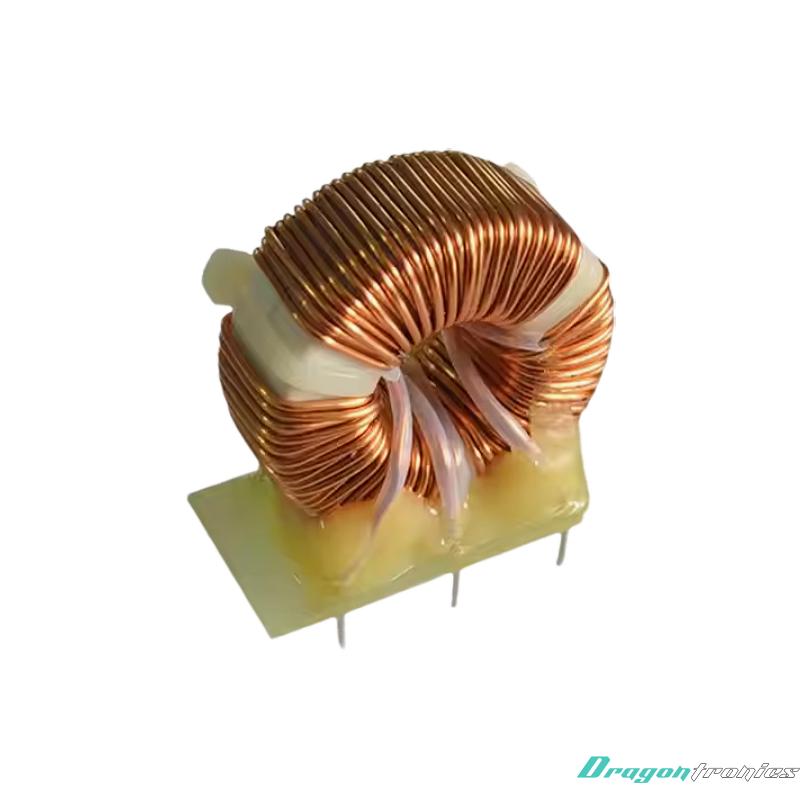

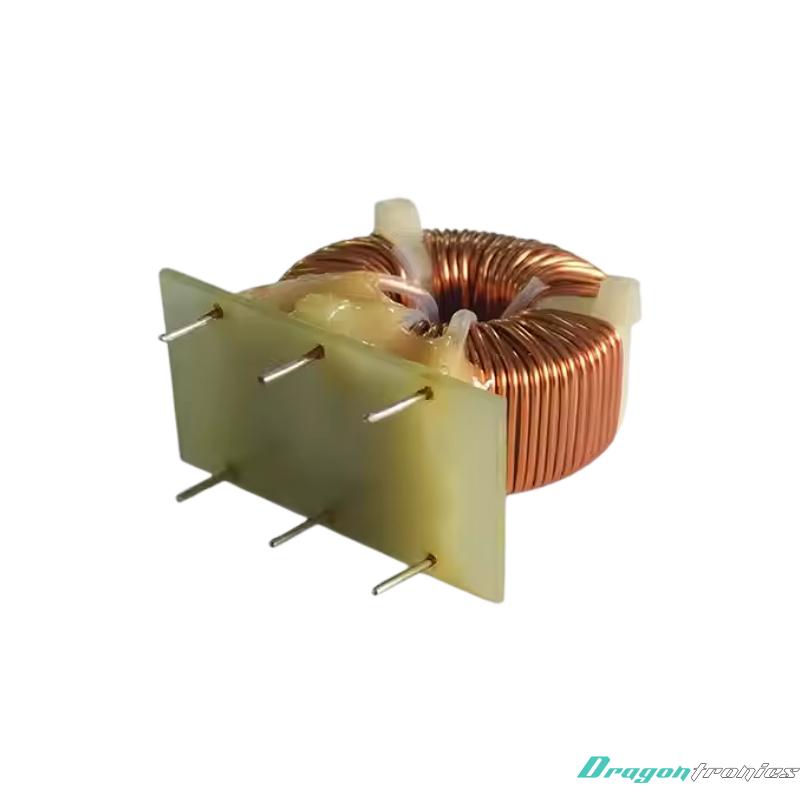

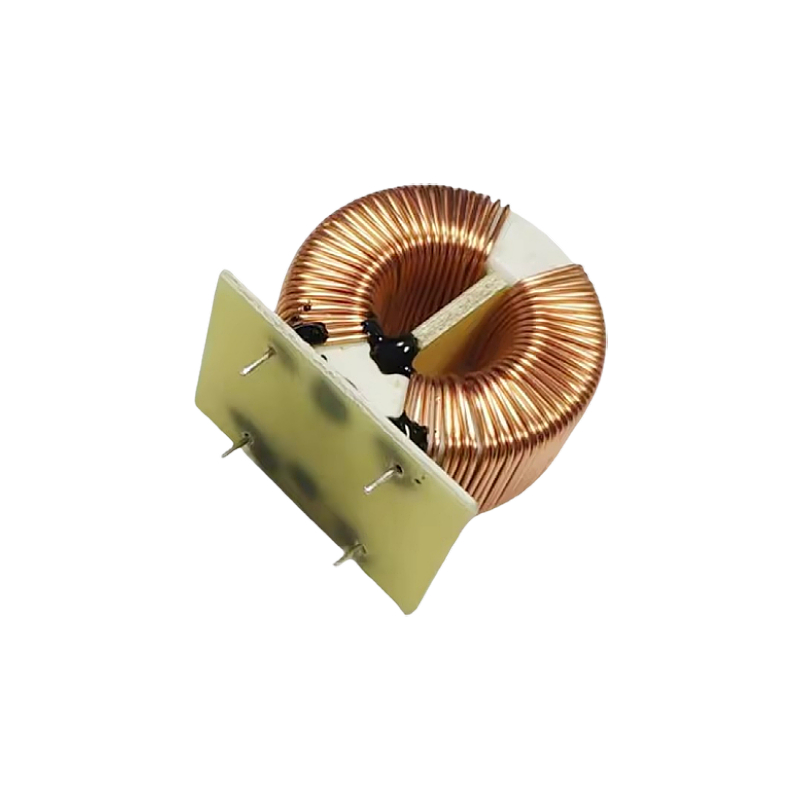

Inductor & Coil

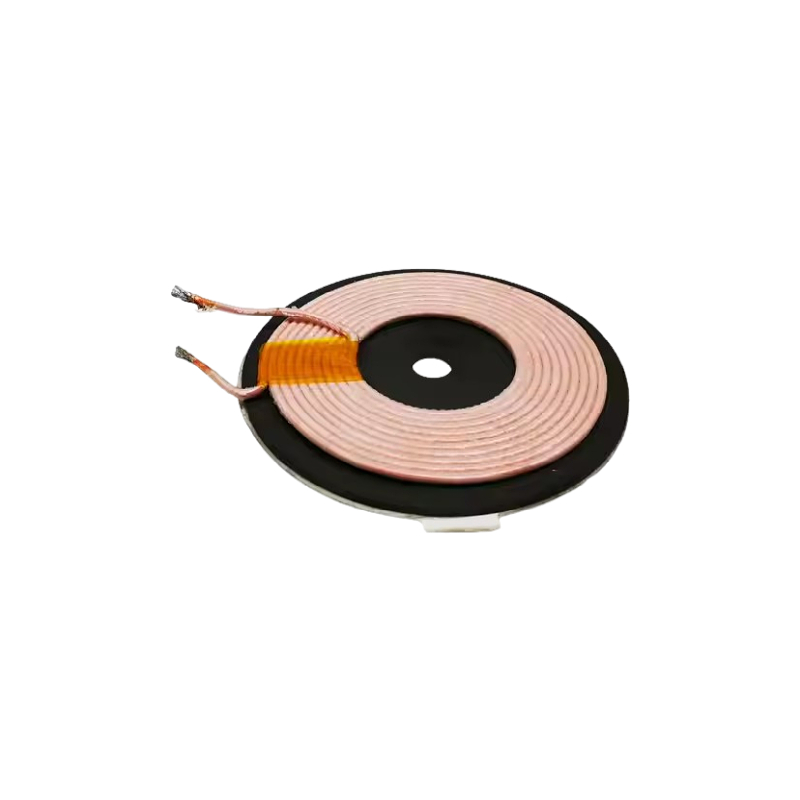

Magnetic High Current Inductor with FR4 base

- Product description: A Magnetic High Current Inductor with an FR4 base is a specific type of inductor designed to store energy in a magnetic field while handling high current levels. The FR4 base refers to the material us

How magnetic high current inductor with an FR4 base works:

1. Inductive Reactance:

o When an alternating current (AC) or pulsed current is applied to the inductor’s windings, the inductor resists changes in current due to its inductive reactance. This happens because the changing current creates a changing magnetic field, which in turn induces a voltage (back EMF) that opposes the change in current.

o The inductance (measured in henries, H) of the inductor is determined by the number of turns in the coil, the core material, the core geometry, and the air gap (if any). The higher the inductance, the more the inductor resists changes in current.

2. Magnetic Field Creation:

o When a current flows through the copper wire windings, a magnetic field is created around the wire due to Ampere’s Law. The magnetic flux generated by the current passes through the core material (such as ferrite or iron powder) and is stored as magnetic energy.

o The core material is chosen to maximize the inductance by ensuring that the magnetic field is confined and amplified within the core rather than leaking into the surrounding air. This allows for a more compact design while increasing the energy storage capability.

3. Energy Storage and Release:

o An inductor stores energy in its magnetic field when a current flows through it. When the current decreases or is interrupted, the magnetic field collapses, releasing energy back into the circuit.

o In a high current inductor, this means the component can store and release large amounts of energy, which is essential in applications like power supplies, filtering circuits, and DC-DC converters.

4. Thermal Management:

o High current inductors can generate significant heat due to resistance in the copper windings and losses in the core material. The FR4 base plays a role in dissipating some of the heat, though FR4 itself is not the most thermally conductive material. As such, inductors designed for high currents may use additional features like larger surface areas for heat dissipation, or heat sinks for better cooling.

o Some inductors may also use air gaps in the core material to limit core saturation and improve heat dissipation.

5. Saturation and Core Material:

o The core material used in high current inductors is designed to avoid core saturation, which occurs when the magnetic field becomes too strong for the core material to handle, causing a loss of inductance and potentially damaging the inductor. The material’s magnetic saturation point is a critical factor in determining how much current the inductor can safely handle.

o For high-current applications, the core material is carefully chosen to handle higher flux levels without saturating, ensuring that the inductor remains efficient at storing and releasing energy.

Applications: High-current inductors with an FR4 base are commonly used in applications where high efficiency and compactness are important. These include:

1. Power Supplies: Used in buck converters, boost converters, and buck-boost converters to smooth out the current and filter noise in power supply circuits.

2. DC-DC Converters: In power regulation circuits, especially for high-power devices, these inductors are critical in ensuring stable voltage output while minimizing ripple.

3. Filtering Applications: Used in EMI (electromagnetic interference) filtering to smooth out noise and ensure the clean operation of sensitive electronics.

4. Motor Drives: In power conversion for electric motors, particularly where high current flows are involved, such as in electric vehicles or industrial machinery.

5. Wireless Charging: In wireless power transmission, high-current inductors are used to transfer power between coils with high efficiency.

Advantages of FR4 Base in High Current Inductors:

1. Structural Stability: FR4 is a strong, durable material that holds the inductor’s components together, preventing mechanical failure under high-current conditions.

2. Electrical Insulation: It offers good electrical insulation, preventing short circuits or unintended connections between windings.

3. Thermal Resistance: While not as thermally conductive as metal, FR4 can still handle the heat generated by high current applications and contributes to the overall heat management strategy.

4. Cost-effective: FR4 is a relatively low-cost material compared to metal cores, making it an attractive choice for mass production of inductors.

Conclusion:

A Magnetic High Current Inductor with an FR4 base works by storing energy in a magnetic field created when current flows through its copper windings, with the magnetic field concentrated and supported by a magnetic core. The FR4 base provides structural support, electrical insulation, and helps in heat management. This type of inductor is essential in high-power electronics, where its ability to handle large currents and efficiently store and release energy is critical for applications like power supplies, converters, and filtering systems.

Categories

Latest News

Contact Us

Contact: Fiona Wu

Phone: 86 - 173 28414 818

Tel: 86 - 173 28414 818

Add: 20, Changtian Road, Hengli, Dongguan, Guangdong, 523852, China

Lankecms

Lankecms lankecms

lankecms

Lankecms

Lankecms