Inductor & Coil

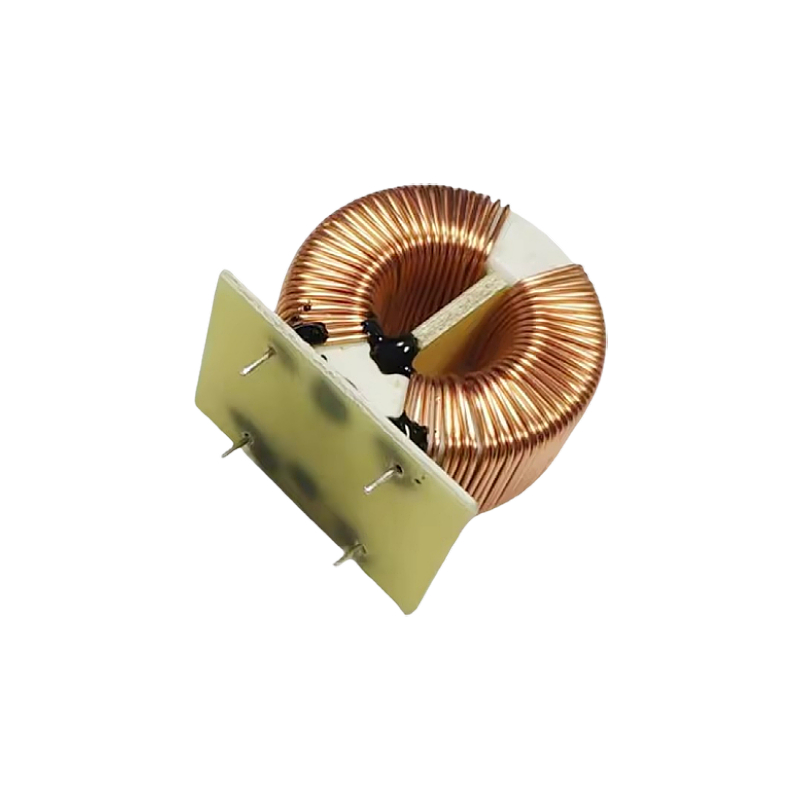

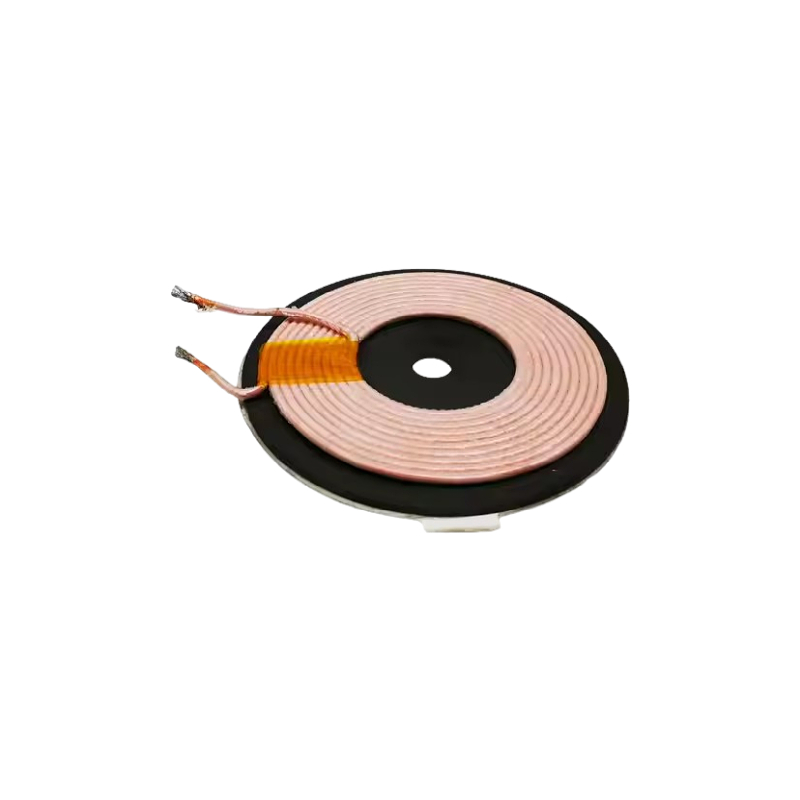

Silk-Coated Wire Choke

- Product description: A silk-coated wire choke is a type of inductor or coil where the wire used for the windings is coated with a layer of silk. The silk coating serves primarily as an insulation material and provides a f

Basic Working Principle of a Choke:

A choke is a type of inductor used to block high-frequency signals while allowing low-frequency signals to pass through. It works by taking advantage of the electromagnetic properties of inductance:

1. When current flows through a wire coil (such as the windings of a choke), it creates a magnetic field around the coil.

2. The magnetic field resists changes in current (i.e., it opposes rapid changes in current flow, especially at higher frequencies).

3. This resistance to changes in current at high frequencies is what makes a choke an effective filter.

The choke essentially blocks or filters high-frequency noise (e.g., electromagnetic interference, or EMI) while allowing low-frequency signals or DC current to pass through more easily.

Role of Silk Coating:

The silk coating on the wire in the choke serves several functions:

1. Insulation: The primary role of the silk coating is to act as an insulator between individual turns of wire in the coil. This prevents short circuits between adjacent turns of wire and allows the choke to work effectively.

2. Reduced Heat Dissipation: The use of silk as a coating can potentially reduce heat dissipation in the choke, as silk can have better heat resistance properties compared to other coatings, depending on the specific material used. This can make the choke more efficient, especially in applications where heat buildup is a concern.

3. Improved Structural Integrity: The silk provides a layer of protection for the wire, helping to maintain the physical integrity of the coil structure. This can increase the choke's durability and resistance to wear and tear over time, especially in environments where the coil may be subject to mechanical stresses.

4. Better Performance at High Frequencies: In some specialized high-frequency applications (like audio equipment or RF circuits), the silk coating could also help with reducing parasitic capacitance or minimizing the eddy currents between the wire turns. This helps improve the choke's performance in filtering unwanted high-frequency signals.

Applications of Silk-Coated Wire Chokes:

Silk-coated wire chokes, though not as common as other types of coated wire chokes, are used in some high-performance applications where their specific properties are valued, such as:

- Audio equipment: High-quality audio equipment often uses chokes with silk-coated wire to minimize electromagnetic interference (EMI) and to ensure clean power delivery to sensitive components.

- RF (radio frequency) circuits: In RF applications, silk-coated wire may be used for inductors and chokes to avoid unwanted interactions with high-frequency signals.

- Vintage electronics: Silk-coated wire is often seen in older electronic devices, including tube amplifiers and early radios, where traditional manufacturing methods were used.

Conclusion:

A silk-coated wire choke works in much the same way as any other inductor by blocking high-frequency currents and allowing low-frequency currents to pass through. The main difference lies in the silk coating, which provides insulation, heat resistance, and structural integrity to the wire, potentially improving the choke's overall performance and longevity in specific applications.

Categories

Latest News

Contact Us

Contact: Fiona Wu

Phone: 86 - 173 28414 818

Tel: 86 - 173 28414 818

Add: 20, Changtian Road, Hengli, Dongguan, Guangdong, 523852, China

Lankecms

Lankecms lankecms

lankecms

Lankecms

Lankecms