Inductor & Coil

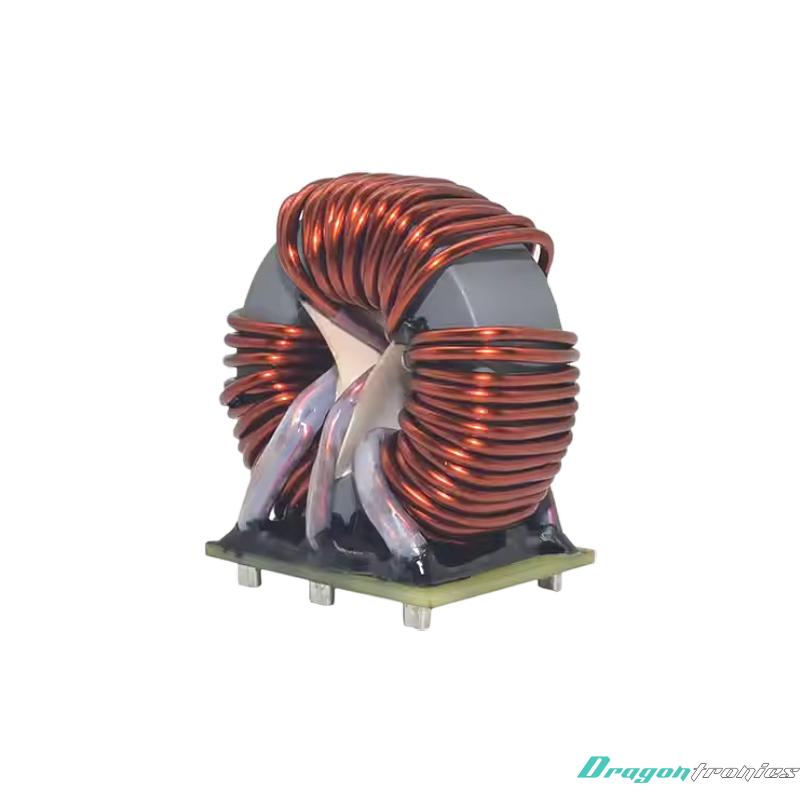

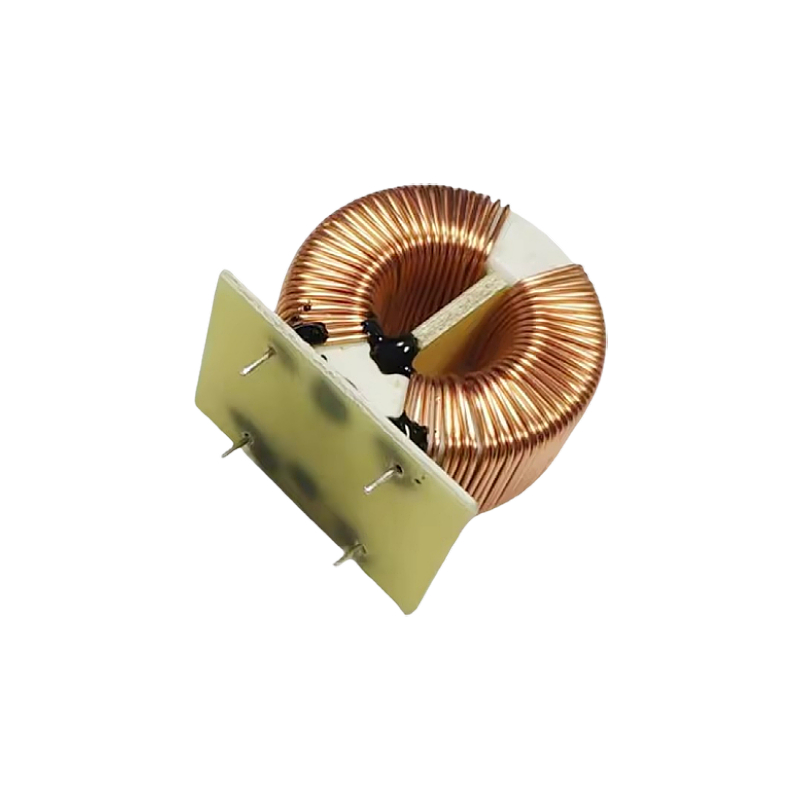

Inductor With FR4 Substrate

- Product description: An inductor with an FR4 substrate combines the properties of an inductor (a passive electronic component that stores energy in a magnetic field) with an FR4 substrate (a type of printed circuit board

Here's how such an inductor with FR4 substrate works:

1. Inductor Basics:

An inductor operates based on the principle of electromagnetic induction. It typically consists of a coil of wire wound around a core (which may be air or a magnetic material like ferrite). When an electric current flows through the coil, it generates a magnetic field around it. The inductor resists changes in current due to the magnetic field, and this property is used in applications like signal filtering, energy storage, and noise reduction.

The key characteristic of an inductor is its inductance (measured in Henrys), which determines how much resistance the inductor offers to changes in current. The inductance is influenced by factors like the number of turns in the coil, the type of core material, and the physical dimensions of the inductor.

2. Role of the FR4 Substrate:

The FR4 substrate provides a structural foundation for the inductor. FR4 is a composite material made of epoxy resin and woven glass fibers, and it's widely used for printed circuit boards (PCBs) due to its excellent insulating properties and mechanical strength. Here's how the FR4 substrate influences the inductor's behavior:

- Mechanical Support: The FR4 substrate serves as the physical base for the inductor, providing a rigid, durable structure for the wire coil. This is important for maintaining the shape and integrity of the coil over time, especially in mass production or environments where mechanical vibrations or shocks are common.

- Insulation: The FR4 substrate acts as an insulator between the coil (which may be connected to electrical signals) and other circuit components. This prevents short circuits or unintended electrical connections between the inductor and other parts of the circuit.

- Thermal Management: FR4 is a relatively good thermal conductor compared to some other PCB materials, though not as good as metal-based substrates. It helps dissipate heat generated by the inductor due to resistive losses or current-induced heating. This can improve the reliability of the inductor, especially in power applications where high currents might cause significant heat buildup.

- Compact Design: Using FR4 as a substrate allows for a compact and integrated design, where the inductor can be embedded in the same PCB as the rest of the circuit. This reduces the need for additional external components and simplifies manufacturing and assembly.

- High-Frequency Performance: In some designs, the FR4 material itself can have a minor impact on the inductor's high-frequency behavior. For example, at very high frequencies, the FR4 substrate may introduce some parasitic capacitance or losses. However, in most practical cases, FR4 is sufficient for moderate-frequency applications and is often chosen for its cost-effectiveness and versatility.

3. Working Mechanism:

When an electric current passes through the inductor (the coil wound around a core or air), it generates a magnetic field. The FR4 substrate helps in the following ways:

- It provides stability to the coil’s structure, ensuring the turns of wire remain in the correct configuration.

- It isolates the coil from the rest of the circuit, allowing the inductor to store and manage energy in the magnetic field without electrical interference.

- It assists in heat dissipation, especially in power inductors, by spreading the heat generated by the current flowing through the wire.

4. Applications of Inductors with FR4 Substrates:

Inductors with FR4 substrates are commonly used in various electronic circuits where inductive properties are needed, and the FR4 substrate provides the necessary structural and insulating support:

- Power Supplies: Used in DC-DC converters, buck or boost converters, and voltage regulation circuits.

- Signal Filtering: For noise reduction in audio, video, and RF circuits.

- Energy Storage: In circuits that require energy storage for later use, such as in switching power supplies.

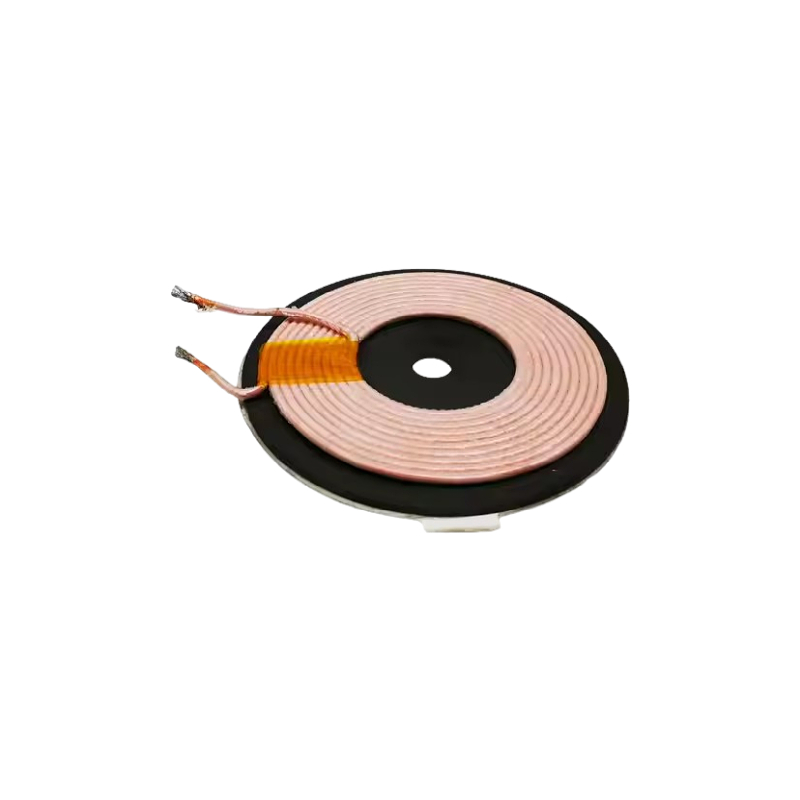

- Wireless Communication: In RF circuits where inductors are used for tuning, filtering, or impedance matching.

- Consumer Electronics: In various electronic devices such as smartphones, laptops, and home appliances.

5. Advantages of Using FR4 Substrate for Inductors:

· Cost-Effective: FR4 is relatively inexpensive compared to other materials, making it a good choice for many consumer and industrial applications.

· Good Insulation Properties: It provides high insulation resistance, preventing electrical leakage and short circuits.

· Durability and Reliability: FR4 is robust, resistant to moisture, and stable under most environmental conditions.

· Integration in PCBs: FR4-based inductors can be easily integrated into printed circuit boards, enabling compact and efficient designs.

6. Limitations of FR4 Substrate:

- Lower High-Frequency Performance: At very high frequencies (RF applications), FR4 may introduce parasitic losses or affect the inductance value due to its dielectric properties.

- Thermal Conductivity: While FR4 has decent thermal conductivity, it is not as effective as metal-based substrates (like copper or aluminum) in dissipating heat in high-power applications.

Conclusion:

An inductor with an FR4 substrate works just like a standard inductor, but with the added benefits of mechanical support, insulation, and thermal management provided by the FR4 material. It is a versatile and commonly used component in a wide range of electronic applications, from power electronics to signal processing, where a stable, cost-effective, and integrated inductor is needed

Categories

Latest News

Contact Us

Contact: Fiona Wu

Phone: 86 - 173 28414 818

Tel: 86 - 173 28414 818

Add: 20, Changtian Road, Hengli, Dongguan, Guangdong, 523852, China

Lankecms

Lankecms lankecms

lankecms

Lankecms

Lankecms