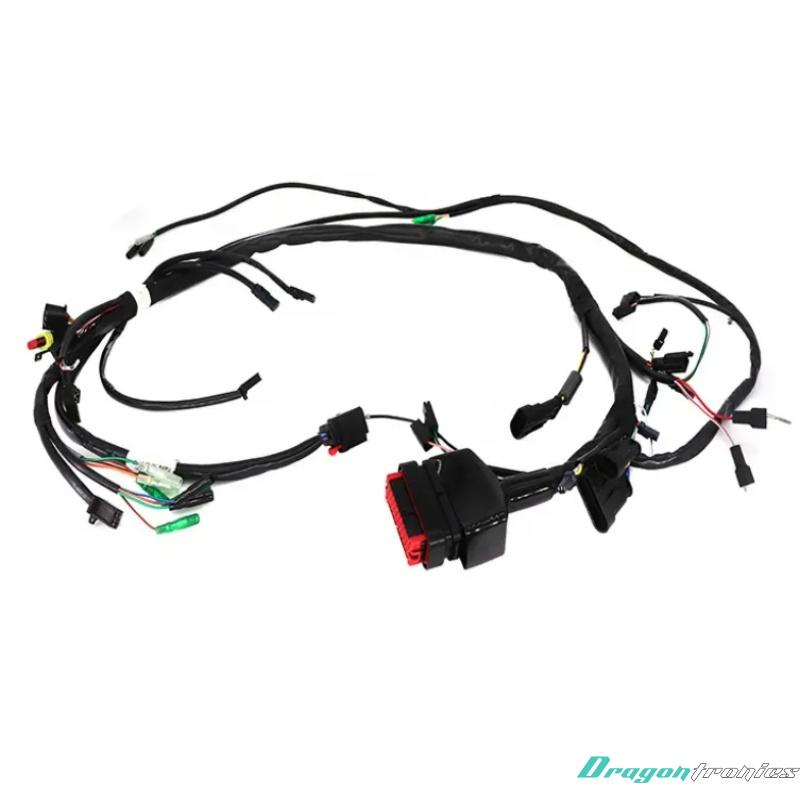

Customized Cable Assembly

Customized Automotive Wire Harness Power Distribution Wiring Harness made according to requirement

- Product description: Customized Automotive Wire Harness Power Distribution Wiring Harness made according to requirement

A Power Distribution Wiring Harness is an essential electrical component used in various systems, including automotive, industrial equipment, and machinery. It serves to distribute electrical power from a central power source (such as a battery or alternator) to various components or subsystems, ensuring the correct flow of electricity to operate devices such as lights, motors, sensors, and control units.

This type of wiring harness is designed to efficiently manage the power distribution within a system, providing the necessary connections and protection (via fuses or relays) to ensure that electrical components work reliably and safely.

Functions of a Power Distribution Wiring Harness:

1. Power Distribution:

o The primary function of a power distribution wiring harness is to distribute electrical power from the central power source (e.g., the battery) to various electrical components or subsystems in the system. This includes components like lights, motors, sensors, and electronic control units (ECUs).

2. Centralized Power Management:

o It centralizes the power supply to various components, reducing the complexity of wiring by organizing and routing electrical connections to different parts of the system efficiently.

3. Protection of Electrical Components:

o A power distribution harness often includes fuses, relays, and circuit breakers to protect against overcurrents, short circuits, or other electrical faults that could damage components or cause system failures.

4. Signal and Power Integration:

o In addition to distributing power, the harness can carry signal wires that control power flow or communicate data between the components and central controllers, like the engine control unit (ECU) in vehicles or controllers in industrial machines.

5. Grounding:

o It helps in the proper grounding of components, ensuring electrical systems operate safely and efficiently by directing excess electricity or faults to the ground.

6. Simplified Wiring Layout:

o The harness reduces the need for individual wiring connections by providing a centralized routing point for power distribution. This makes the wiring system cleaner, more organized, and easier to manage.

Components of a Power Distribution Wiring Harness:

1. Power Wires:

o These wires carry electrical current from the power source (e.g., battery, alternator) to various components and subsystems. The wires are often thick and capable of handling high current.

2. Fuses:

o Fuses are incorporated into the wiring harness to protect the electrical system. They break the circuit if the current exceeds a safe level, preventing damage to sensitive components or fire hazards.

3. Relays:

o Relays are used to control high-current components via low-current signals. They allow the power distribution system to manage devices that require more electrical power than a simple switch can handle, such as motors or lighting systems.

4. Ground Wires:

o Ground wires help complete electrical circuits by providing a safe path for electrical current to return to the vehicle or machine’s chassis, preventing dangerous faults or short circuits.

5. Connectors and Terminals:

o Connectors and terminals ensure that the wiring harness can be easily connected to electrical components and power sources. These connectors often come in various forms, depending on the system’s requirements.

6. Protective Sleeving and Insulation:

o The wires in a power distribution harness are typically insulated or enclosed in protective sleeving to prevent exposure to heat, moisture, abrasion, or other environmental hazards.

Applications of a Power Distribution Wiring Harness:

1. Automotive Industry:

o In vehicles, a power distribution harness is used to distribute electrical power from the battery or alternator to various subsystems such as lights, engines, sensors, infotainment systems, and air conditioning systems. It ensures that each component receives the necessary power and protects against electrical faults.

2. Industrial Equipment:

o In industrial machinery, a power distribution wiring harness can be used to manage electrical power for systems like motors, pumps, valves, sensors, and control panels. It ensures efficient power supply and protection of sensitive components.

3. Aerospace and Military Systems:

o Power distribution harnesses are used in aircraft and military equipment to distribute power to critical systems such as navigation, communication, lighting, and avionics. The harness ensures safety, reliability, and efficiency in demanding environments.

4. Consumer Electronics:

o In large electronic appliances (e.g., washing machines, refrigerators, air conditioners), power distribution wiring harnesses help manage the power supply to various internal components, ensuring that each part receives the correct voltage and is protected from overload.

5. Renewable Energy Systems:

o In solar power systems or wind turbines, power distribution harnesses manage power flow from solar panels or turbines to inverters, batteries, and other components. They ensure efficient power distribution and safe operation of the system.

Conclusion:

A Power Distribution Wiring Harness is an essential part of electrical systems in various applications, from automobiles and industrial machinery to aerospace and renewable energy systems. It centralizes the power distribution, connects electrical components, ensures safe operation, and protects against potential faults or overloads. By simplifying wiring, improving reliability, and enhancing safety, the power distribution wiring harness plays a crucial role in efficiency and longevity of complex electrical systems.

Categories

Latest News

Contact Us

Contact: Fiona Wu

Phone: 86 - 173 28414 818

Tel: 86 - 173 28414 818

Add: 20, Changtian Road, Hengli, Dongguan, Guangdong, 523852, China

Lankecms

Lankecms lankecms

lankecms

Lankecms

Lankecms